Discovering ways to increase productivity across your business is key. One area where operations can be significantly enhanced is in the packaging process. Using a carton sealing machine offers an excellent solution to streamline this part of the workflow, saving time and resources while ensuring a high-quality seal. Here’s how you can maximize your packaging productivity with carton sealing machines.

The Need for an Efficient Packaging Process

Efficient packaging is crucial for several reasons:

-

Time Savings:

Manual sealing of cartons is labor-intensive and time-consuming. Automation can cut down the time required for this process.

-

Consistency and Quality:

Manual sealing can be inconsistent, leading to packaging errors and potential damage during transit. Carton sealing machines provide a consistent and secure seal.

-

Cost-Effectiveness:

By reducing labor costs and minimizing waste, businesses can save significantly in the long run.

Carton Sealing Machine Benefits

-

Increased Speed and Efficiency:

Carton sealing machines can handle high volumes of packaging in a short period. This increased speed can significantly boost overall productivity. Automated machines can operate continuously without fatigue, unlike human workers.

-

Improved Accuracy and Consistency:

Machines ensure that each carton is sealed with the same precision, reducing the risk of errors that can occur with manual sealing. Consistent sealing helps maintain product integrity during shipping, reducing the chances of damage and returns.

-

Cost Savings:

While the initial investment in a carton sealing machine may seem high, the long-term savings in labor costs and reduced material waste make it a cost-effective choice. Automation reduces the need for extensive training and oversight, further cutting down operational costs.

-

Enhanced Safety:

Carton sealing machines reduce the risk of repetitive strain injuries and other health issues associated with manual packaging tasks. By automating the sealing process, you can create a safer work environment for your employees.

Choosing the Right Carton Sealing Machine

To maximize the benefits, it’s important to choose the right machine for your needs. Consider the following factors:

-

Volume and Speed Requirements:

Evaluate the volume of cartons you need to seal daily. High-volume operations will benefit from fully automatic machines, while smaller operations might find semi-automatic machines sufficient.

-

Carton Size and Type:

Ensure the machine can accommodate the size range of the cartons you use. Some machines are adjustable and can handle a variety of sizes.

-

Material Compatibility:

Different machines use different types of sealing materials such as tape or glue. Choose a machine that is compatible with your preferred sealing method.

Featured Case Sealers

BestPack™ AS Series – Carton Sealing Machine

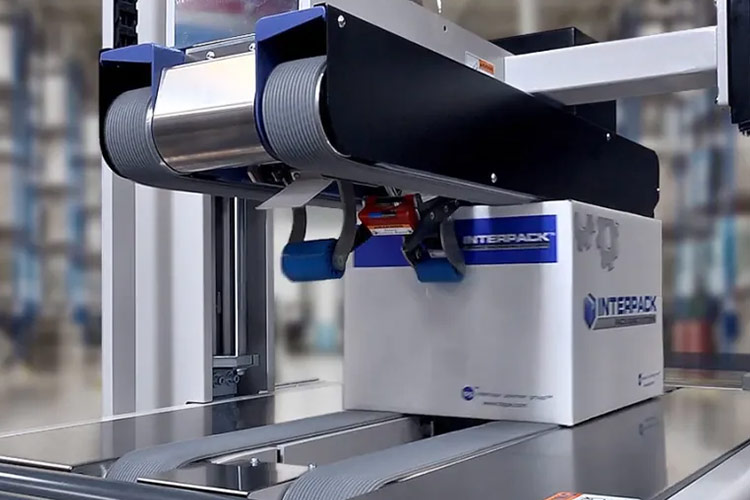

A fully automatic carton sealer designed to meet the needs of uniform in-line carton closure applications. Designed with a solid four-column support structure and using dual motor side belt technology, the AS closes all four top flaps and seals the top & bottom of the carton, using 45-60 PSI and 4-5 SCFM of air.

IPG RSA Series – Carton Sealing Machine

Heavy duty operator fed machines that automatically adjust for each size case processed. Faster throughput in today’s changing world is key to a successful operation. This new case sealer was designed to offer faster processing speeds with improved pneumatics which allows for faster bridge rise and smoother descent onto the top of the case.

3M-Matic™ Adjustable Carton Sealing Machine

Designed to seal the top and bottom center seams of up to 40 uniform regular slotted containers per minute. A heavy duty gear motor provides power to the bottom belt drive, and adjustable side guides position and align your boxes for quick and easy throughput.

Should You Invest in a Carton Sealing Machine?

Investing in carton sealing machines is a strategic move for any business looking to enhance its packaging efficiency. The time savings, cost reductions, and improved quality that these machines provide can significantly boost your productivity and overall operational success. By choosing the right machine and implementing it effectively, you can streamline your packaging process and stay ahead in the competitive market.