What is a carton erecting machine?

Carton erecting machines, also known as a carton erector or case erector, is a piece of automated equipment used to form flat-packed cardboard boxes into their intended shape. The machine takes flat carton blanks and folds, forms, and seals them to create ready-to-fill boxes. This automation saves time and labor, enhancing overall production efficiency.

Types of Carton Erecting Machines

1. Manual Carton Erectors

Manual carton erectors require human intervention to load the flat carton blanks and initiate the forming process. They are suitable for small to medium-scale operations where budget constraints or lower production volumes don’t justify fully automated systems.

2. Semi-Automatic Carton Erectors

Semi-automatic carton erectors strike a balance between manual and fully automatic machines. While they require some manual input, such as loading the blanks, the machine handles the folding and sealing processes. These are ideal for businesses that need to increase efficiency without a significant investment in fully automated equipment.

3. Fully Automatic Carton Erectors

Fully automatic carton erectors are designed for high-volume production lines. They handle the entire process, from loading the blanks to forming, folding, and sealing the cartons. These machines are equipped with advanced features like touch-screen controls, adjustable settings, and integration with other packaging line equipment.

Key Features and Benefits

1. Increased Efficiency

Carton erecting machines significantly boost production efficiency by automating the time-consuming task of forming cartons. This allows for a higher throughput and reduces labor costs.

2. Consistency and Precision

Automated machines ensure uniformity and precision in carton formation, reducing errors and minimizing material wastage. Consistent carton quality is crucial for maintaining product integrity during shipping and handling.

3. Versatility

Modern carton erecting machines are versatile and can handle various carton sizes and shapes. Adjustable settings and quick-change features make it easy to switch between different packaging requirements.

4. Space-Saving Design

Many carton erectors are designed with compact footprints, making them suitable for production lines with limited space. Their ergonomic design also enhances ease of use and maintenance.

5. Enhanced Safety

Automated carton erectors come with safety features such as emergency stop buttons, protective guards, and sensors to prevent accidents and ensure operator safety.

Considerations for Choosing a Carton Erecting Machine

1. Production Volume

Assess your production volume to determine the level of automation required. High-volume operations benefit from fully automatic machines, while lower volumes may justify manual or semi-automatic options.

2. Carton Size and Shape

Ensure the machine can handle the range of carton sizes and shapes your business uses. Some machines offer customizable settings to accommodate various dimensions.

3. Budget

Consider your budget constraints. While fully automatic machines offer the highest efficiency, they also come with a higher initial investment. Weigh the long-term benefits against the upfront costs.

4. Integration

If you already have an existing packaging line, ensure the carton erector can integrate seamlessly with other equipment, such as case packers, conveyors, and palletizers.

5. Maintenance and Support

Choose a machine from a reputable manufacturer that offers reliable customer support and maintenance services. Regular maintenance is crucial for keeping the machine running smoothly and minimizing downtime.

Featured Carton Erectors

BestPack™ ELVS Carton & Case Erector

This erector is built for heavy usage with quick and simple carton size changeover. There are no tools required for carton size changeover. The ELVS handles a wide range of carton sizes.

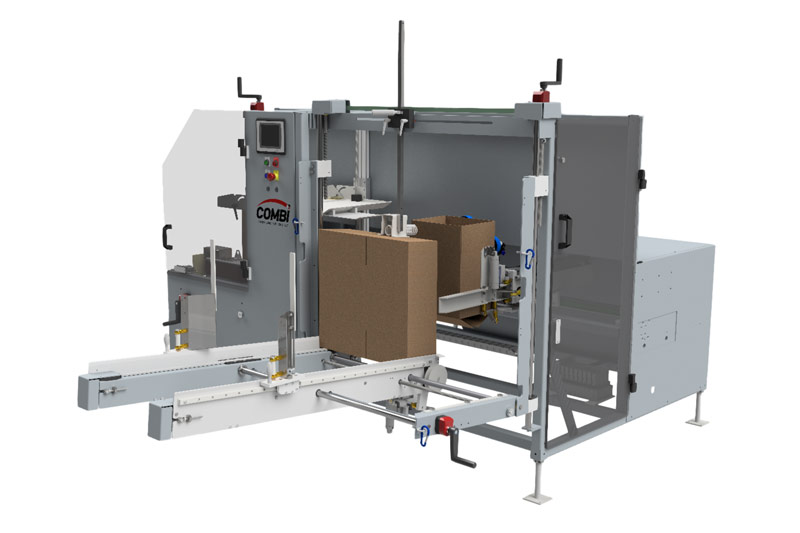

Combi 2-EZ® HS Series

Combi’s high speed case erector models, the 2-EZ® HS 20, 2-EZ® HS 25, and 2-EZ® HS 30, utilize servo motors to form and bottom seal cases at speeds up to 30 cases per minute.

Wrapping it Up

Investing in a carton erecting machine can revolutionize your packaging operations, enhancing efficiency, consistency, and overall productivity. By understanding the different types of carton erectors and considering key factors such as production volume, carton size, budget, and integration needs, you can make an informed decision that aligns with your business goals. Embrace the power of automation and take your packaging process to the next level with the right carton erecting machine.

Schedule a free consultation with Flexpak’s equipment expert to learn more about carton erecting machines!